Find This Product Here!

High-precision MT-Touch Switch NEW!!

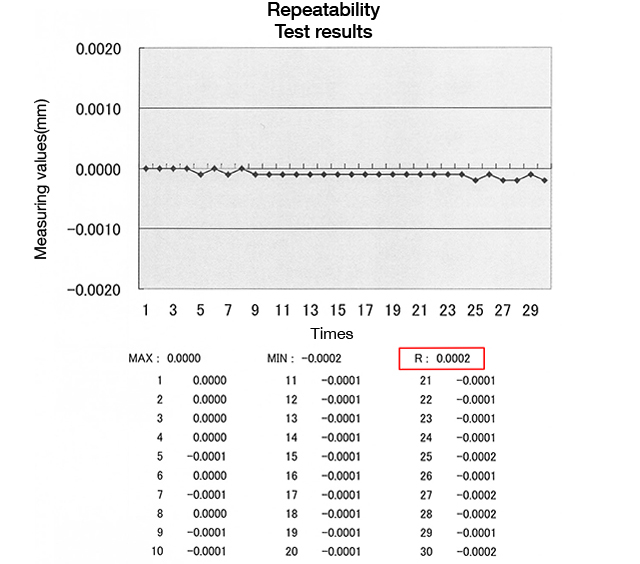

0.0005㎜ repeatability, dulable under harsh environment!

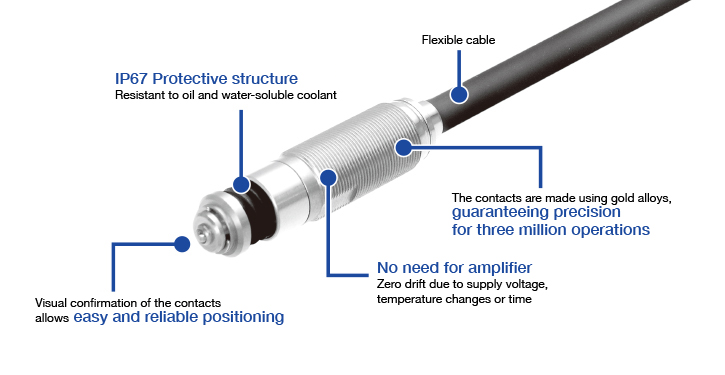

Precision mechanical type with no electronic components. IP67, can be used in harsh environment.

An industrial-use mechanism which supports work at manufacturing sites.

One of the most essential elements when it comes to improving product quality and productivity is 'positioning'.

Precision positioning can be extremely difficult to achieve, even with the latest digital technologies.

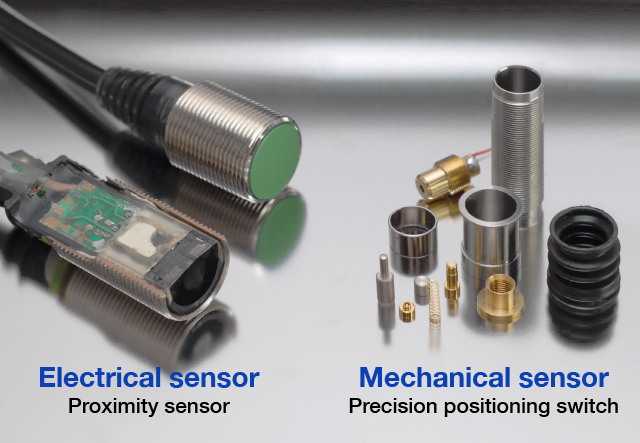

This is where Metrol's 'Precision Positioning Switch" steps up.

The switch boasts high repeatability, helping improve the accuracy and automation of industrial machines, at an entirely reasonable price.

Metrol's flagship product, the High Precision MT-Touch Switch, was a groundbreaking product among precision touch switches.

It is a precision mechanical type with no electronic components.

It offers repeatability of 0.0005 mm, with zero temperature drift or deviation due to self-heating.

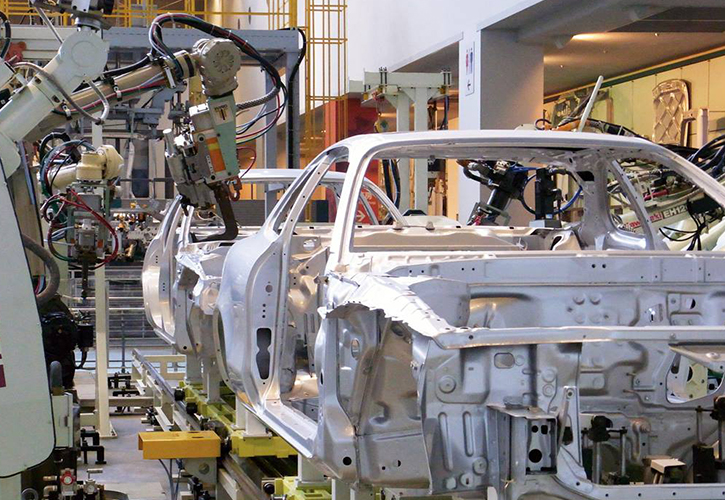

The IP67 structure handles harsh conditions such as exposure to spattering water, coolant, or cutting chips, delivering precision positioning, even in harsh environments such as use with CNC machine tools or on automotive production lines, etc.

In fact, the High Precision MT Touch Switch was born out of a joint-development process with Toyota Motor Corporation.

Development of the switch began shortly after the establishment of our company back in 1977.

It was at the behest of Toyota Motor Corporation's First Production and Engineering Department that development began.

At the beginning, Metrol was a small company with just a few employees, generally handling single-product design orders.

However, it was difficult to generate much in the way of revenue with single-product design alone, and with the company falling deeper into the red, it seemed only a matter of time before we would be forced to call it a day.

It was against this dire financial background that Toyota Motor Corporation stepped in with their development request.

"Would you be able to make us a reliable signal gauge (dial gauge with signal function) that can stand up to tough usage conditions?"

The signal gauges used at Toyota's car manufacturing plants are measuring instruments initially designed for the express purpose of preventing mistakes with the use of OK/NG indicator lamps during offline inspection processes involving manual pass/fail judgments.

As such, if the gauge's water- and dust-proofing functions were not up to scratch, they would not work in the harsh conditions found on automotive production lines, leading to multiple breakdowns.

Frequent short stoppages were causing big problems.

Conformity evaluation as part of development was carried out by Toyota Motor Corporation, including demands that we at Metrol deliver repeatability within 1 μm per 1 million operations.

Given the standards to which we worked at that point, these demands seemed beyond us.

"This is our opportunity to show our abilities as engineers and artisans!"

The engineers came out fighting, determined to develop a high precision dial gauge able to withstand harsh conditions as demanded by Toyota.

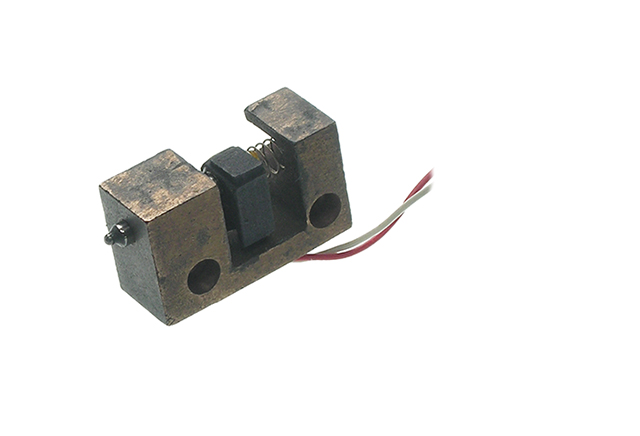

We got busy designing the "MT-Pulser", a product incorporating two compact switches manufactured overseas.

The incorporation of the two switches allowed us to create a ground-breaking new product that was able to take the three pass/fail classes (+NG, OK, and -NG) and split them into just two separate categories (±NG and OK) without the use of a PLC.

However, as the prototypes were evaluated, a number of issues came to the surface.

"We can't keep the signal for long..."

The reason for this became apparent when we disassembled the product and investigated.

The internal switches, manufactured overseas, were fragile and quick to break under even the slightest excess force.

These expensive switches became absolutely useless in no time at all...!

The components were imported from overseas as well, and we weren't confident we could guarantee a continued supply.

"Why don't we just make low-cost switches ourselves that won't break so easily?"

And with that, we began the internal development of switches.

Putting aside the excitement and unease felt throughout the company toward meeting this challenge, our engineers set forth with one solid conviction...

Not to simply emulate the offerings of other companies.

And with that resolution, they tackled the problems at hand.

An original structure was designed from scratch, with robustness vastly improved from that of other companies' easily breakable switches.

This was how we developed our first switch.

That first switch became the prototype for all future "precision positioning switches".

We had managed to resolve the issue of durability with our first switch and meet Toyota's harsh demands regarding repeatability.

However, the essential waterproofing performance of our switches was still not exactly up to scratch.

And so we developed a completely sealed structure featuring O-rings and rubber boots able to withstand the harsh conditions found on automotive production lines.

In this new design, we used a special type of rubber compatible with oil- and water-soluble coolants.

We then incorporated this switch into the "MT-Pulser", delivering both "high-precision detection" and "strength able to withstand adverse and harsh conditions"!

In order to bring this switch, the fruits of our hard work in development, onto the market, we had to make a number of additional improvements, producing the High Precision MT-Touch Switch.

We changed the exterior of the switch to a cylindrical shape in order to make it easier to mount, delivering an IP67 protective structure with repeatability of 0.5 µm.

As it is assembled using only precision mechanical parts, there is zero temperature drift due to self-heating!

Metrol was established in 1976 with the aim of creating products with global reach.

The development of the High Precision MT Touch Switch for precision positioning was the realization of that dream.

What set us apart from other companies was that, instead of simply emulating others, we got our heads down and worked steadily.

Working on the small things each and every day delivers unbounded potential!

The High Precision MT-Touch Switch was built with meticulous attention by our engineers.

If you are wondering where Metrol's positioning switches originated, look no farther.

Precision mechanical type with no electronic components. IP67, can be used in harsh environment.

Our experienced engineers will be more than happy to assist you.

+81 50 5558 7366

Monday - Friday 8:30-17:30 JST.

+81 42 528 1442

Write down your questions