Detects workpiece seating in CNC lathe chucks with ±1μm accuracy

Agricultural machine industry

A machine component manufacturer that produces engines for agricultural machines.

A representative of crank shaft production section consulted us on "seating confirmation".

Table of Contents

Client’s Issues

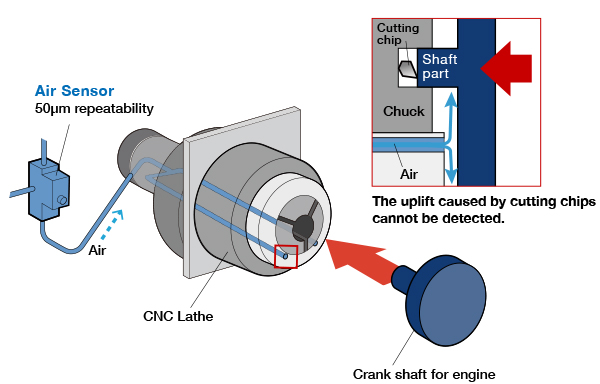

When milling engine crank shafts, an air sensor was used to detect any float in the seating due to cuttings between the workpiece and chuck.

We received an inquiry after a sales visit, looking for a solution to the problem of the current air sensor (repeat accuracy of 50μm) which was not handling the accuracy demands of the end user as they were raised from 100μm to 35μm.

While the end user demanded accuracy of 35μm, seating confirmation with repeatability of 10μm or better was requested to allow for machining tolerance.

The main focus of the issues

Workpiece seating confirmation with 10µm repeatability is necessary when chucking in lathe.

Metrol’s suggestions

Air sensors used with CNC lathes are largely used for checking the work chuck when machining;

however, in reality most are designed for "existence detection" and not suitable for "precise confirmation of adhesion".

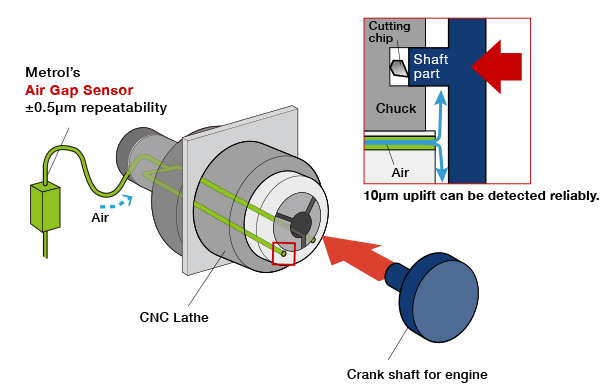

Metrol's "Air Gap Sensors" demonstrate ±0.5 μm repeatability which is 10 times as precise as that of conventional "air sensor".

Precision turning process can be realized by stably detecting 10µm gap caused by cutting chips put between the workpiece and the chuck.

Improvements

By confirming workpiece seating with 10μm repeat accuracy, improved lathe accuracy can be achieved.

Comment from Metrol representative

Many of on-site engineers have said that "confirmation of adhesion" of workpieces by the "air sensor" intended for detecting a presence of workpiece impairs the accuracy and makes the precision machining difficult.

Like the cases introduced here, "Air Gap Sensors" have been widerly adopted not only by agricultural machine industry but also automobile manufactures that require a high-accuracy "machining of the hybrid engine" or "turning process of ABS components".

We provide the rental service of samplings for the evaluation.

Please feel free to contact us.

For further information about the products used in this application

Air Gap Sensor [Short range detection type]

10μm gap caused by foreign materials can be detected with contactless switches.

Precision seating confirmation of jig and workpiece can be realized.