Wafer damage can be prevented by positioning with ±0.5μm repeatability

Semiconductor industry

A semiconductor device production manufacturer that produces a Demounter Device for removing the semiconductor wafer from the substrate.

A mechanism designer contacted us with some questions regarding positioners for demounter drives.

Table of Contents

Client’s Issues

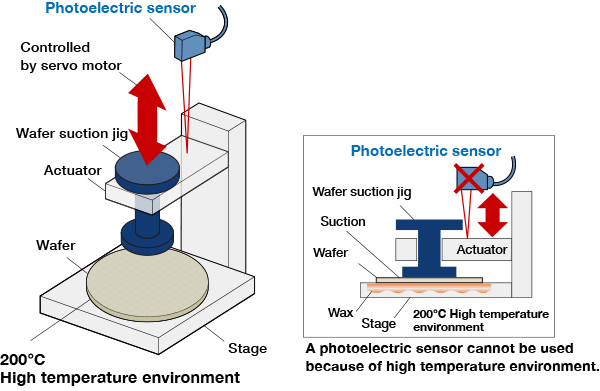

A servo motor controls a vacuum suction jig when removing the wafer from the stage by vacuum suction;

however, they were running into problems with damage to the wafer under the weight of the jig.

The device melts the wax holding the wafer and stage together, resulting in a 200°C or higher high temperature environment.

They considered using a photoelectric sensor for positioning of the suction jig, but couldn't achieve the precision required due to the high temperature of the environment.

The wafer was damaged even under light loads, making positioning with ±1μm repeat accuracy essential.

When he was looking for high precision sensors, he got to know Metrol product by the visit our booth in "Positioning EXPO 2015".

The main focus of the issues

The height of the wafer suction jig should be detected with ±1μm repeatability.

200℃ high temperature environment makes it difficult to use a photoelectric sensor.

Metrol’s suggestions

Optical sensors such as photoelectric sensors and laser sensors are easily affected by the external environment and are not suitable for micron level positioning in high temperature environments.

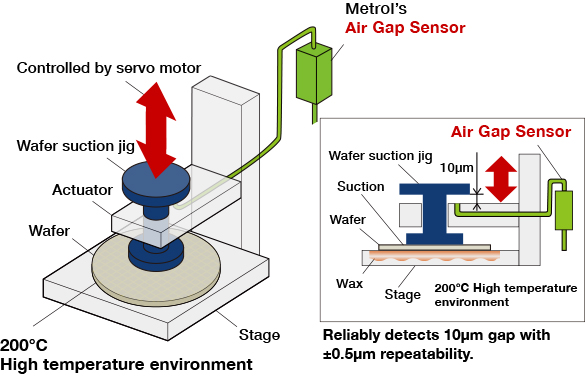

Metrol's "Air Gap Sensor" is a non-contact sensor which demonstrates ±0.5µm repeatability.

Attach a nozzle to the drive and install the Air Gap Sensor in a position not affected by the temperature.

Detection of the gap between the suction jig and drive through changes in air pressure allows precise positioning with ±0.5μm repeatability even in a 200°C high temperature environment.

By positioning the vacuum suction jig precisely, it is possible to prevent breakage of the wafer.

Improvements

Detects the wafer suction jig height with ±0.5μm accuracy using high precision gap detection.

Exhibits consistent accuracy even in 200°C high temperature environments.

Comment from Metrol representative

We often hear from sites using vacuum deposition devices and sputtering devices, saying "I want a highly accurate sensor that works in high temperature environments!" from industries not limited to that of semiconductors.

The "Air Gap Sensor" introduced here exhibits high accuracy even in 200°C high temperature environments.

Capable of detecting seating with accuracy at high temperatures, with multiple proven track records in diverse fields including detecting 10μm gaps in press molds and detecting mold alignment.

Retrofitting is possible by opening an air nozzle in the detector.

If you have any trouble with "positioning""gap detection", under high temperature enviroment, please feel free to contact us.

For further information about the products used in this application

Air Gap Sensor [Short range detection type]

10µm gap can be detected reliably!

Realize "Precision seating confirmation" of the jig and workpiece.