Effectively detects seating of rough workpieces to within ±5μm accuracy

Automobile industry

A precision machining manufacturer that produces engine parts for major automakers.

A reperesentative of production of sleeve parts consulted us on "seating confirmation" when chucking the workpiece on CNC lathe.

Table of Contents

Client’s Issues

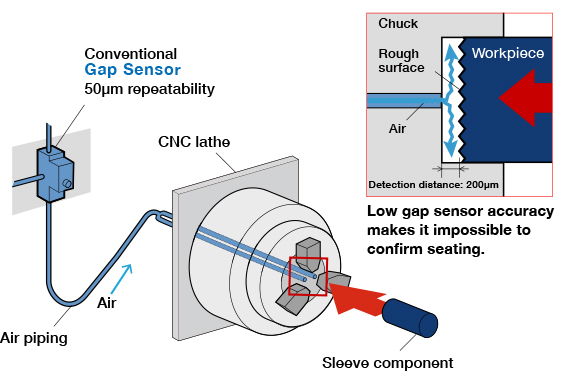

A pneumatic gap sensor was used to verify the seating of engine transmission sleeve components on the work chuck when machining using a CNC lathe.

Because of the rough workpiece surface, the seating detection distance was configured at 200μm, lowering the sensor accuracy and leading to frequently occurring problems due to poor seating.

We received an inquiry after a sales visit, looking for a solution to the problem of the current pneumatic gap sensor.

The main focus of the issues

Workpiece roughness leads to large accuracy variations in the pneumatic gap sensor.

Faulty detections lead to poor machining or caused machinery to halt.

Metrol’s suggestions

Most of "pneumatic gap sensor" adopted on CNC lathe as a standard equipment is intended for "existence detection" of workpieces and is not suited for "precise seating confirmation".

The rougher the surface of the workpiece, the higher the risk of faulty detection.

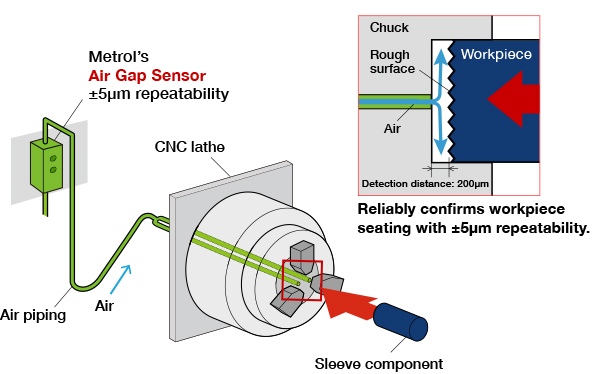

Metrol's Long Range Air Gap Sensor supports long-distance detection at distances of 80 to 350μm.

±5μm accuracy can be obtained to ensure effective detection of workpiece seating even with rough materials such as die-cast components or castings.

In addition, use in pre-existing air piping is possible, eliminating the need for bothersome air pipework design and making installation easy.

Seating confirmation of the sleeve casting surface effectively prevents machining errors from occurring.

Improvements

Exhibits seating precision of ±5μm even with rough-surfaced workpieces.

Precision seating confirmation prevents processing defects.

Comment from Metrol representative

For further information about the products used in this application

Air Gap Sensor [Long range detection type]

Reconsider everything you thought you knew about "Gap Sensors".

Stably detect gaps of 80 to 350µm between a rough surface workpiece or large workpiece and jigs.