Detected the deviation of the X-Y axes of the machining table with 0.5µm repeatability

Automobile industry

An automobile components manufacturer that produces engine parts for a major automaker.

A representative of the production engineering department consulted us on "positioning" of the machining table of the tapping center.

Table of Contents

Client’s Issues

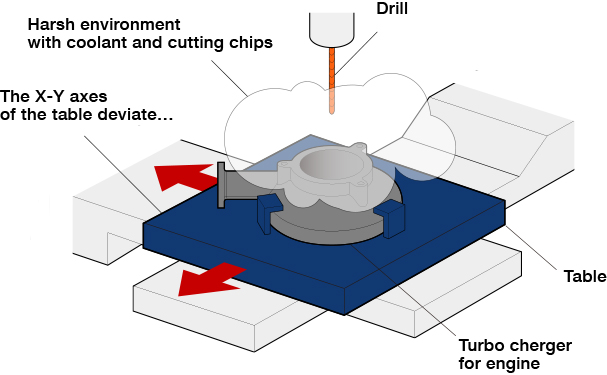

The client has a trouble with the deviation of the X-Y axes of the machining table during machining the turbo charger for engine by the tapping center.

Although "Proximity sensors" or "Optical sensors" were also considered, under harsh working conditions in the machine tool where coolant and cutting chips splatter, frequent false detections prevent stable positioning of the table.

Even a slight deviation of the table results in lowering the product quality.

The client inquired us looking for a sensor capable of precision positioning even under harsh environments.

The main focus of the issues

Micron-level deviation of the machining table should be detected.

Harsh environment with coolant and cutting chips causes false detections when using noncontact sensors.

Metrol’s suggestions

False detections due to splattering of coolant and metal cutting chips often occur when using sensors inside machine tools.

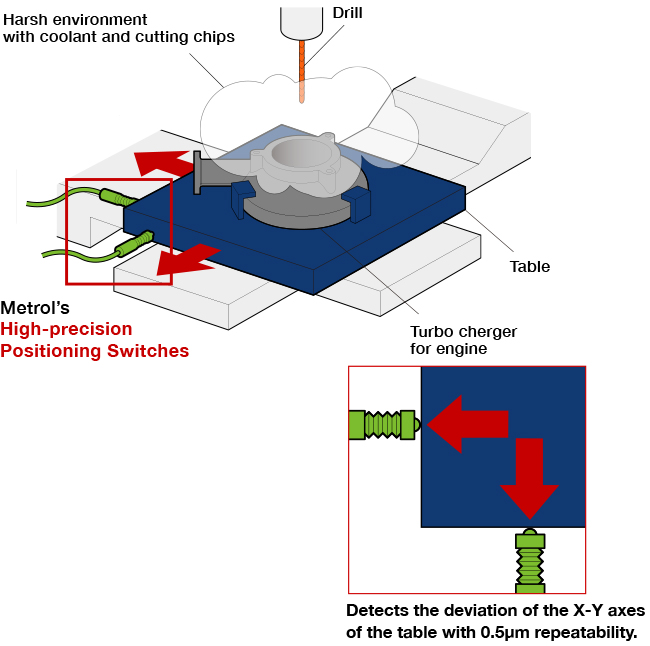

Metrol's "High-precision Positioning Switch" is a contact type waterproof switch sealed with fluororubber which has high durability against coolant.

The switch is capable of stable positioning even under harsh working conditions with coolant and cutting chips by contating the machining table directly.

High-precision machining of the turbo charger can be realized with 0.5µm repeatability.

Improvements

Detects the deviation of the X-Y axes of the table with 0.5µm repeatability.

Stable detection can be realized with the contact type switch even under harsh environmant with coolant and cutting chips.

Comment from Metrol representative

As stated already, the "High-precision Positioning Switch" has been widely used for positioning under harsh environment in machine tools in applications such as "tool wear detection" for machining centers and "measuring of the end surface" of the workpiece on the CNC grinding machine.

For further information about the products used in this application

High-precision Positioning Switch [MT]

0.5µm repeatability!

Stable detection can be realized even under harsh environment with coolant and cutting chips.