Features

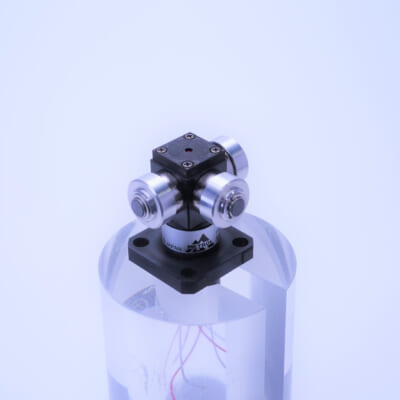

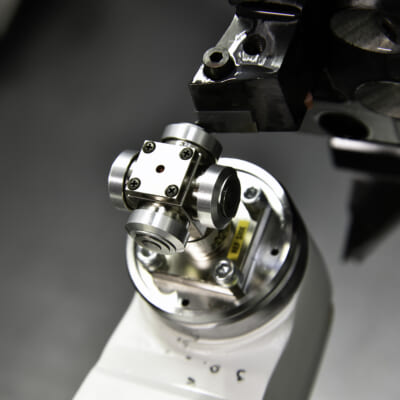

Customization available up to 5 directions of detection

The direction that the contact-surface faces can be selected from 1 to 5 directions depending on the equipment and environment in which it is mounted.

ONLY METROL provides customization to fit your needs regarding the mounting space and the contact-surface directions for the tool.

Repeatability of 1μm and coolant-resistant IP67 protection rating spec.

It performs speedy and automatic tool measurement before starting machining and in-machine tool compensation during the machining cycle.

The IP67 rating ensures high-precision detection even in adverse environments where coolant is applied, contributing to time savings in tool setting.

High reliability + Low cost: Fewer false detection achieved by touch sensor method

Since the detection is made by direct contact with the tool’s leading edge, coolant splatter or mist is less likely to interfere when comparing with expensive non-contact sensors (e.g., laser sensors), thus ensuring high reliability.

Awarded the Director General of Science and Technology Agency Award and has shipped over 100,000 units total thus far and counting.

Since its development in 1983, the H4A series has been continuously refined in areas of water resistance and precision and it has been the go-to product for many major machine tool manufacturers across the globe, with over 100,000 units shipped to over 74 countries thus far and counting.

![Tool Setter for CNC lathes [H4A Series]](https://metrol-sensor.com/wp-content/uploads/2021/01/img_products_tool_setter_h4a.png)

![CNC旋盤用ツールセッター[H4Aシリーズ]の回路図](https://metrol-sensor.com/wp-content/uploads/2021/03/ad234c0958c8ebc59734e6473506e3cf.png)

![CNC旋盤用ツールセッター[H4Aシリーズ]のカスタマイズ](https://metrol-sensor.com/wp-content/uploads/2021/03/customize_H4A_en.jpg)